The demand for short development cycles and the low cost of new models promote the development of auto-modular platforms. Automotive modular platforms include the assembly and design of sub-systems of a car in a more modular way and according to the positioning of models.

Unlike traditional automotive platforms that are only for models at the same level, modular platforms reduce production and R&D costs while shortening the development cycle of a new model. Subsequently, it improves the strength of products and unifies quality standards.

What Defines Automotive Platforms?

Various companies define architectures and platforms differently. But automakers in America classically define automobile platforms as a set of shared dimensions between the driver’s hip-point, Crowl, and front axle centerline.

A simple motivation for sharing automotive platforms is to maximize ROI on engineering. Leveraging expense of developing unseen structural elements, including everything supporting the bodywork. This helps to maximize profits and reduce costs, and if done well, may allow vehicles to be manufactured on the same equipment.

Communizing commercial fleet electrification and assembly-plant equipment helps simplify workforce training and improve product quality. It can also improve manufacturing flexibility, allowing the development of common models to be expanded to other companies creating the same platforms.

What Modular Platforms Include

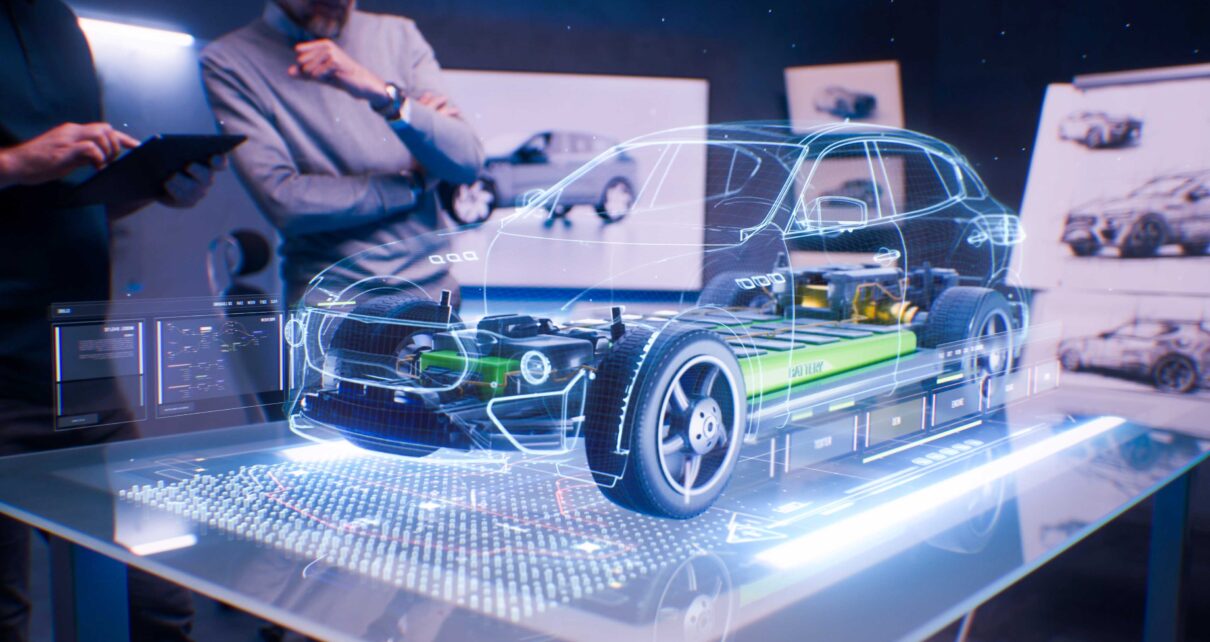

Modular platforms determine a lot of important components of a vehicle. It offers a solid foundation on which a car design is implemented. Mostly, the modular platforms contain the following components:

- Types of suspension at the rear and front of the car

- Drivetrain components

- Drive unit’s location

- Engine type

- Power steering system

- Wheelbase

- Rear and front axle design

Floor plates are often confused with the chassis of the car. However, in practice, they are two different things. The work of floor plates is to designate the key attachment points for different components, including electrical harnesses, seat belts, steering columns, engine, and suspension. The dimension of a car also depends on the floor plate.

How Modular Platforms Change the Automotive Industry

Modular platforms for EVs can decrease the development strain so as to encourage vehicle diversity and electric vehicle development, thereby hastening transfers away from internal combustion cars. To better understand how modular platforms change the automotive industry, look at the following key points:

- Flatbed assembly – Skateboard platforms have become popular modular platforms among vehicle manufacturers, including Tesla, Byton, and Rivian. When it comes to this platform, the bed length may decrease or increase based on the model and the entire assembly of the vehicle.

- Support various body designs – Placement of lower batteries on modular vehicle platforms may optimize better digital functions as well as driving balance. Such modular platforms may accommodate any body type on the top design. Fleet owners, service providers, tech partners, OEMs, and EV manufacturers may use unlimited options to create effective vehicular designs.

To Wrap-Up

With the ever-changing powertrain options, consumer needs, and technological advancements, the decision-making and manufacturing strategies are bound to be complex. Therefore, t is best to do an extensive assessment of manufacturing strategies while considering the product strategy, investment considerations, and production volume.